BENEFITS OF ATS3C AUTOMATED system

Increased Accuracy and Consistency:

Provides precise control over testing parameters, ensuring consistent results and reducing variability associated with manual methods.Compliance:

Automation enhances compliance by improving precision, consistency, and traceability. This aligns with our company’s motto: “Compliance through Automation.”High-Accuracy Testing:

Delivers exceptional precision with 24-bit high-resolution data acquisition hardware, Shunt calibration for each transducer, and accuracy verification of torque transducers and data acquisition hardware anytime between tests.

Data Integrity:

Automatically generates digital test reports, graphs, and self-diagnostic logs. This eliminates manual, error-prone processes and ensures accurate, secure, and easily retrievable test data.Versatility:

Tests various nuts, collars, Hi-Lok fasteners, Eddie nuts, and other threaded components. The software includes dozens of tools for programming complex tests, enabling multiple fastener types to be tested on the same equipment.

Reduction of Human Error:

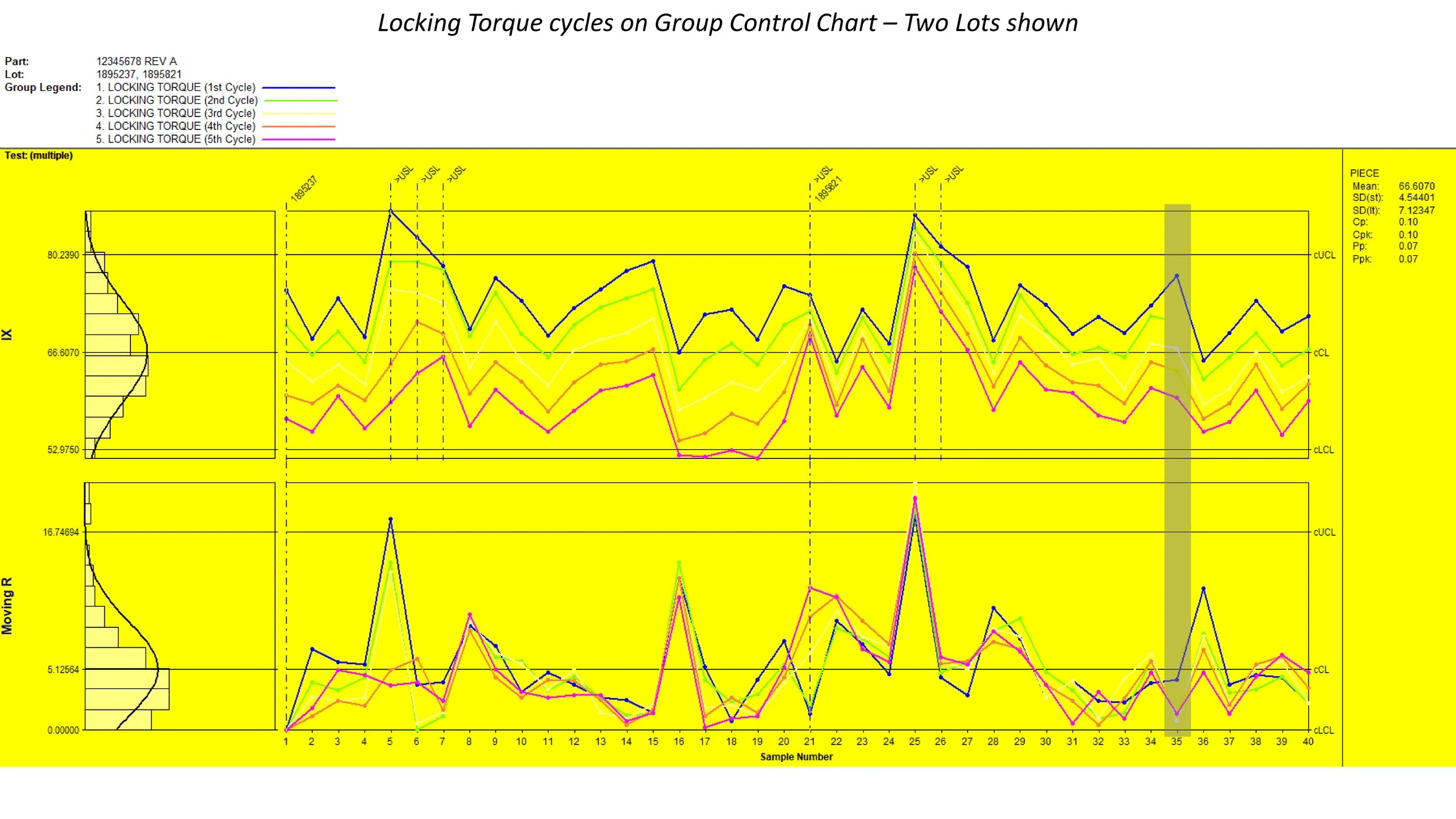

Minimizes risks such as inconsistent torque application and incorrect data recording.Advanced Data Collection and Analysis:

Produces digital test reports with statistical calculations. Test data can be automatically transferred to Statistical Process Control software for detailed analysis.Predictive Maintenance:

Automatically creates a system performance log for each test sample. Continuous recording of process data predicts system failures, enabling timely maintenance.Improved Workplace Safety:

Reduces physical demands on workers, lowering the risk of injuries.